IMAGO Printer is the largest Polish manufacturer of flatbed printing devices with 10 years of experience in developing inkjet printer designs. During this time, we have accumulated enormous know-how in the field of digital printing technology through our own experience and completed courses and training with specialists in the industry. The result of our many years of development is the optimization of the design and production process, thanks to which the devices manufactured in our plant are characterized by high quality. We focus on building long-term relationships with our clients, assistance and advice in every area of operation, and joint development.

Top quality devices

The devices we manufacture are made of the highest quality industrial parts, and each of them undergoes a series of standardized tests and calibrations before it reaches the customer.

Equipment tailored to the customer's needs

A wide range of our solutions means that everyone will find something for themselves. We offer both UV LED printers, industrial anodized aluminum printing devices and confectionery plotters used in the food industry.

Complex customer service

We provide our clients not only with high-class devices and technical support, but also technological support in the field of adapting our technologies to the customer’s needs.

DISCOVER THE NEXT GENERATION OF FOOD PRINTING

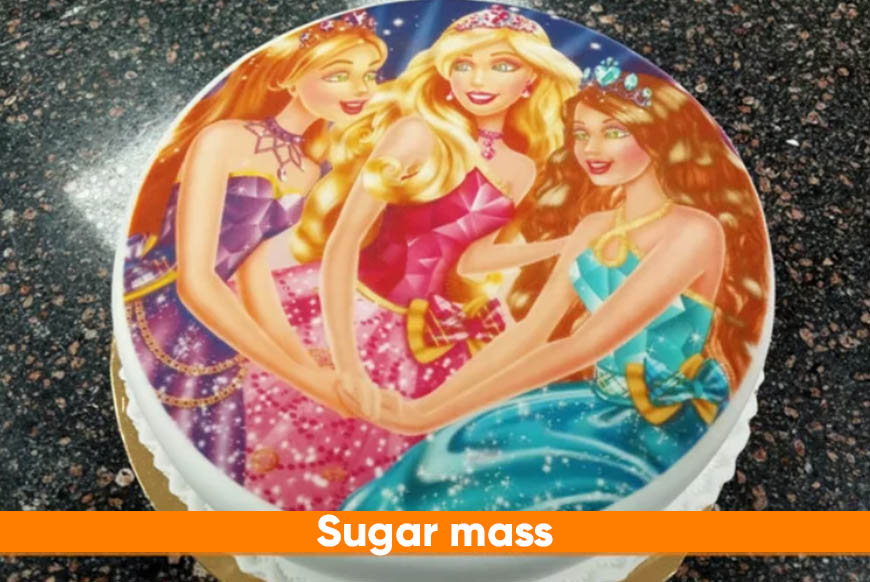

Confectionery plotters are modern devices that allow you to print in photographic quality on virtually any confectionery substrate. Our machines are designed from scratch by experienced engineers associated with the digital printing industry for many years. We are the only Polish company that produces confectionery plotters. We took care of the smallest details to eliminate competition errors and introduce a good product to the market that will allow the development of the Polish confectionery industry.

EXAMPLES OF THE USE OF PRINTING DIRECTLY IN CONFECTIONERY

AQUILA ECO-SOLVENT

It is an ideal solution for both small businesses and large businesses. Find out how Aquila can change your production. Prints on: anodized aluminum, plastics, wood, candles, leather, whatever you want!

FEATURES OF THE AQUILA ECO-SOLVENT PRINTER

THE HIGHEST PRINT QUALITY IN SERIAL PRODUCTION

With AQUILA ECO-SOLVENT, you can make your production on countless materials. The device has been equipped with all the elements necessary for serial printing – copy support and industrial automation of product positioning. The use of appropriately selected inks guarantees photographic print quality and vivid, natural colors on various types of substrates. Additional support is provided by AcroRIP V10.5 print process control software.

EASY TO USE TROUBLE-FREE OPERATION

To learn how to use AQUILA ECO-SOLVENT, all you need is a short, basic training. In addition, our training videos will help you in all problematic situations! Easy access to consumables ensures trouble-free operation and the possibility of independent replacement of elements. A comfortable semi-automatic cleaning system increases the life of the print head, and the system of non-drip bottles and properly selected inks results in low operating costs.

THOUGHTFUL DESIGN

Solid workmanship and a durable structure designed by Polish engineers mean that the machine will serve you for many years, even with the greatest intensity of serial production. A large, well-marked workspace with a ruler works with a dedicated overlay in the Affinity Designer graphics program, and enables precise and repeatable printing on each product.

PRINT ON ANODIZED ALUMINUM

Create nameplates, building markings, control panels or tombstones on anodized aluminum with AQUILA. Thanks to the use of accessories: VSG and a TECHNOLOGICAL BATH, which allow you to heat up and close the pores of aluminum sheets, you will get the highest quality indestructible print on the market. The device is also equipped with a dehumidifier, allowing you to work with highly saturated graphics.